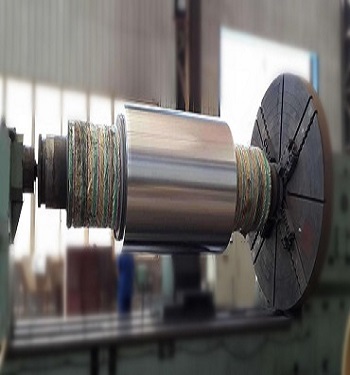

S.G Iron Rolls are available in a wide range of hardness & composition for a variety of application. These Rolls are essentially an Indefinite Chill type material, but with the Graphite in Nodularform instead offlake and having alloyed with higher % of Nickel & Molybdenum along with Carbon.. The matrix structure varies from Ferrito-Pearlitic, Pearlitic to Bainitic & Martensitic together with different carbide contents and graphite in the form of spheroids/nodules. Some critical grades are heat treated for higher strength. These rolls are very much suitable for the rolling of row products with wide range of applications due to its hardness penetration, good wear resistance and tough necks, this material has become a benchmark.

Application of SG IRON PEARLITIC ROLLS include :

| |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Grade | HS Range | C | Mn | Si | P | S | Ni | Cr | Mo | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pearlitic | 40-50 | 3.0/3.3 | 0.3/0.5 | 1.5/2.4 | 0.10 Max. | 0.015 Max. | 1.5/2.0 | 0.15-0.35 | 0.25/0.4 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pearlitic | 50-60 | 3.0/3.3 | 0.3/0.5 | 1.5/2.4 | 0.10 Max. | 0.015 Max. | 1.5/2.0 | 0.25-0.50 | 0.25/0.4 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pearlitic | 60-70 | 3.10/3.50 | 0.6/1.00 | 1.2/1.8 | 0.10 Max. | 0.015 Max. | 1.5/2.5 | 0.3-0.80 | 0.3/0.5 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pearlitic | 70-75 | 3.10/3.50 | 0.6/1.00 | 1.2/1.8 | 0.10 Max. | 0.015 Max. | 1.5/2.5 | 0.3-0.80 | 0.3/0.5 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||